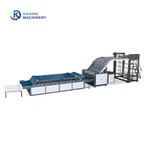

Paper Core Pipe Manufacturing Machine

Products Description

Today, we will introduce one of our paper core pipe manufacturing machine to practitioners and entrepreneurs who want to produce paper tubes. Let's learn about it together.

Feeding device: used to place and transport original paper or paper rolls. Generally, it includes a bracket for placing paper rolls and guide rollers for guiding paper into the machine to ensure that the paper can smoothly enter the machine according to the set path.

Pre-stretching device on the paper core pipe manufacturing machine: usually composed of one or more groups of rollers. Before the paper enters the main process such as winding, the paper is preliminarily stretched to make the paper tighter and smoother, so as to prepare for the subsequent winding of better quality paper tubes and ensure the strength and appearance flatness of the paper tube.

Winding device:Spiral paper core pipe manufacturing machine: There is a rotating part, which winds the pre-stretched paper into a spiral shape through high-speed rotation to form the basic shape of the paper tube. The rotation speed can be adjusted according to the needs of producing paper tubes of different specifications.

Gluing device of paper core pipe manufacturing machine: including components such as glue tank, glue roller or nozzle. The glue roller rotates under the drive of the motor, takes the glue out of the glue tank and applies it on the surface of the paper; the nozzle can spray the glue evenly on the paper, so that the paper can be firmly bonded together when winding, ensuring the structural strength of the paper tube.

Cutting device: composed of a knife and a drive mechanism. When the paper tube reaches the set length, the drive mechanism drives the knife to move and cut the paper tube. The knife usually adopts a circular knife design, such as a single circular knife or a double circular knife, and the cutting method includes synchronous cutting, etc., to ensure that the cut is neat and without warping.

Tube withdrawal device: After the paper tube production is completed, it is used to remove the paper tube from the core shaft or mold. It usually adopts a mechanical structure or pneumatic device to push or pull the paper tube to separate it from the core shaft for easy collection and subsequent processing.

Control system on paper core pipe manufacturing machine: generally composed of PLC, human-machine interface, sensors, etc. PLC, as the control core, receives signals from sensors, such as paper arrival signal, paper tube length signal, etc., and controls the actions of various components according to the preset program, such as motor start and stop, speed adjustment, cutting timing of the tool, etc.; the human-machine interface is used for operators to set parameters and monitor the operating status of the equipment.

Transmission system on the paper core pipe manufacturing machine: including motor, reducer, transmission shaft, belt, chain and other components. The motor provides power, reduces the speed and increases the torque through the reducer, and then transmits the power to various working parts through the transmission shaft, belt or chain, such as the guide roller of the feeding device and the rotating parts of the winding device, to ensure that each component can operate at the set speed and mode.

Working principle

Feeding principle for paper core pipe manufacturing machine: The motor drives the guide roller of the feeding device to rotate, and uses the friction between the guide roller and the paper to pull the paper off the paper roll and convey it forward along the set path. The conveying speed can be adjusted through the control system to adapt to different production processes and paper tube specifications.

Pre-stretching principle: When the paper passes through the rollers of the pre-stretching device, due to the spacing between the rollers and the difference in rotation speed, a certain pulling force is applied to the paper, so that the paper is stretched to a certain extent in the length and width directions, eliminating the wrinkles and unevenness on the surface of the paper, and improving the compactness and uniformity of the paper.

Winding principle for paper core pipe manufacturing machine:Spiral winding: In the spiral paper tube machine, the pre-stretched paper is fed into the rotating device, which drives the paper to make a spiral motion around the core shaft. At the same time, the paper is gradually wound around the core shaft to form a spiral paper tube under the action of its own flexibility and gluing. As the winding proceeds, the diameter and length of the paper tube continue to increase.

Gluing principle: The glue roller or nozzle in the gluing device, under the control of the control system, applies glue evenly to the paper surface according to the set glue supply and application method. Glue plays a bonding role in the paper winding process, so that the adjacent paper layers are firmly combined together to form a paper tube with certain strength and stability.

Cutting principle for paper core pipe manufacturing machine : When the paper tube is wound to the set length, the control system will send a cutting signal to drive the cutter of the cutting device to move. The cutter cuts the paper tube at a certain speed and force, and cuts the paper tube from the continuous winding state into a single paper tube of the required length.

Uncoiling principle for paper core pipe manufacturing machine: The uncoiling device starts working after the paper tube is cut. Through mechanical push rods, pneumatic pistons and other devices, a force is applied to the paper tube to separate from the core shaft, so that the paper tube falls off the core shaft, completing the production process of the paper tube. The fallen paper tube can be transported to the designated location through the conveying device for collection and subsequent processing.

If you are interested in our paper core pipe manufacturing machine,pls feel free to contact us!

Products Parameter

Products Details

Our Company

FAQ

Q: How many languages does your machine support?

A: Our machine supports all the languages.

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;

2. Skilled&experienced engineers&workers;

3. Mature QC system;

4. Specially-assigned merchandiser;

5. Advanced production workshop.

Q: How long it will take to produce machine?

A: Delivery time largely depends on the machine type, for some small machine like manual stitching machine, manual banding machine etc, usually we have stock available.

But for the large machines like carton printing die cutting machine, automatic stitching machine etc, it usually takes around 35-50 days to produce.

Hot Tags: paper core pipe manufacturing machine, China paper core pipe manufacturing machine manufacturers, suppliers, factory, Automatic Folding Gluing and Stitching Machine for Corrugated Cartons, Fingerless Electric Heating Corrugated Single Facer Machine For Corrugated Paper Line, automatic carton box printer slotter die cutter, carton box strapping machine, 2800mm Manual Paper Feeding Semi Automatic Folder Gluer Machine, Efficient Semi Automatic Folder Gluer Machine for Double pieces Cardboard

You Might Also Like

Send Inquiry